RTM Injection

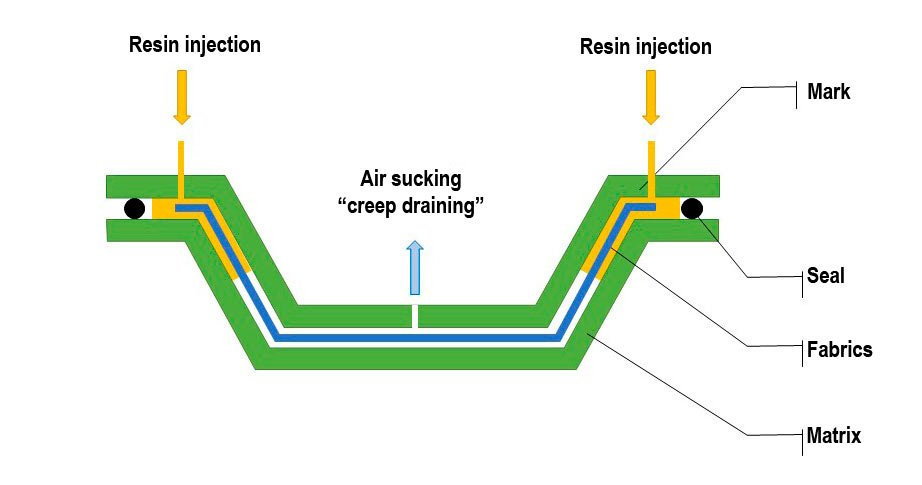

Resin Transfer Moulding is a manual or semi-automated process carried out between rigid mould and counter tool.

Reinforcements, in the form of mats, fabrics or preformed items are placed in the mould chamber. The mould is then securely closed and the catalysed resin is injected inside under low pressure (1.5 to 4 bar).

Several techniques are associated with this process, in particular the Eco RTM, for which vacuum is used to close the mould and alleviate the constraints due to injection, therefore reducing cost, lightening tooling or increasing performance. The applications are for the large distribution of containers, hoods, etc., for high performance, such as tennis rackets, aircraft structural beams, etc.

Avantages

- Two smooth sides

- Low labour-dependent manufacturing process

- Consistent production quality

- Parts are reproducible

- Moderate investments depending on the level of automation

- Higher productivity than contact moulding or vacuum infusion techniques

- Low VOC emissions

Disadvantages

- No undercuts possible

- Reinforcement rate and average characteristics