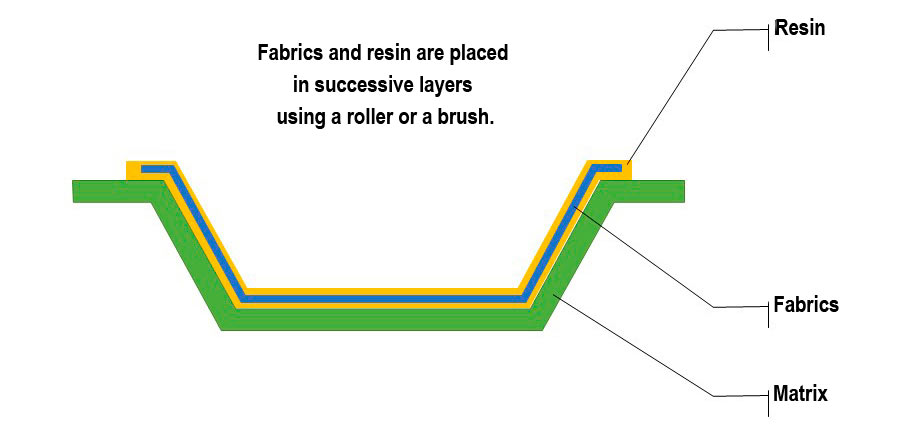

Hand lay up

Hand lay-up technique is the oldest method of composite manufacturing. It allows the manufacture of parts of all shapes and sizes for small series. The mould surface, treated by release agent, receives the surface layer (gel-coat), then the reinforcement in the form of successive layers of mats or fabrics that are impregnated with resin, usually by hand, to obtain the required thickness. After curing at room temperature or with external heat, the mould is opened and the composite is removed from the mould surface.

While the operation is relatively easy to implement and inexpensive in terms of materials, it requires skilled labour. This process can be used to produce large diffusion parts, generally made of fibreglass and polyester resin with a single smooth side.

Les applications

- Vehicle body, fairing

- Various cowling, interior cover

- Boat hull

- Urban furniture

- Sanitation

- Small industrial equipment

Avantages

- Large possibilities of shapes and sizes

- Suitable for shapes with undercuts

- Mechanical properties: good to average

- Low investments

Inconvénients

- Only one smooth side

- Composite part finishing process necessary

- Quality depending on the workforce

- Limited production speed

- High VOC emissions