infusion

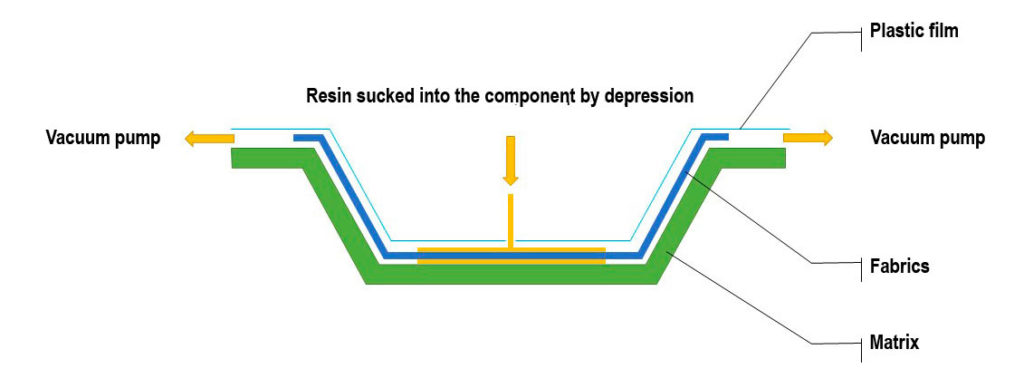

Infusion moulding is a modern process for manufacturing composite materials. It consists of placing dry reinforcements in a mould covered by a vacuum bag which will then be impregnated with the arrival of resin which is sucked up by the depression created in the mould. This technology allows the production of monolithic parts (low and high thickness), such as sandwich structures.

The advantages of infusion compared with contact moulding are:

- a higher fibre rate due to the definable amount of resin used, offering a better strength-to-weight ratio.

- production of large parts in a single step

- Parts are reproducible

- A better protection of the operators against solvent emissions such as styrene. VOC standards.

This technology allows the use of various matrices: unsaturated polyester, vinyl ester and epoxy. The difficulties encountered lie in the installation of the components (mechanical and others), in the infusion process (vacuum and infusion ramp process) as well as in the management of the brakes (geometry of the mesh).

Applications

- Sports

- Aeronautics

- Recreational vehicles

Advantages

- Excellent mechanical properties

- Numerous possibilities of shapes

- No dimension limits

- Low investments

- Simple moulds

- Low VOC emissions

Disadvantages

- Only one smooth side

- Limited production speed

- Waste (consumables)